Kakishibu

Persimmon tannin dye

"Kakishibu" is a traditional Japanese dye/paint of deep amber color which comes from unripe persimmons that have been fermented and aged for more than 2 years. Recently, Kakishibu has been recognized as a great alternative to synthetic colors by more people interested in nature and wellness because it has many natural, beneficial properties, such as deterring insects and having an anti-mold effect for wood and cloth.

The Versatility of Organic Dye Revived After Generations

“柿 KAKI is a persimmon,

渋 SHIBU means astringent.”

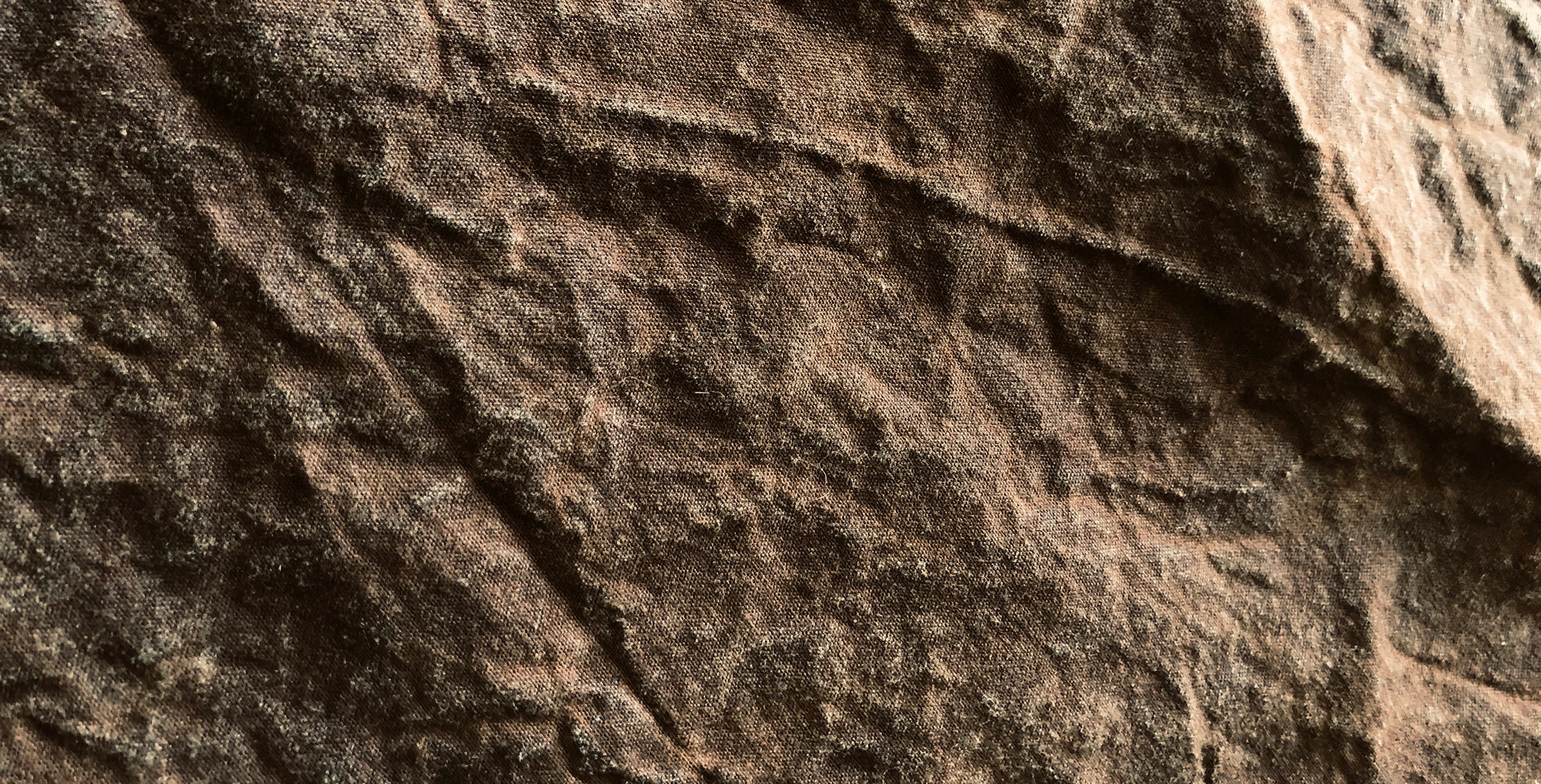

Kakishibu is a traditional dyeing method using the discoloration caused by oxidation of the fermented juice of unripened persimmon fruit containing strong tannin. It also reacts to sunlight, so the color changes slowly with time and sun exposure. Historically, Japanese people enjoyed the changing colors and texture of the natural reactions after one week, one month, and one year later. However, because of fast-paced consumer society, Kakishibu traditions disappeared for many years. Loop of the Loom is proud to offer Kakishibu dye to revive the wisdom of our ancestors who coexisted with nature.

Kakishibu dye had been produced in many places throughout Japan dating back to the 13th century and used in many ways including coating farm equipment, fishing nets, and stencil-making; as a primer for Japanese lacquer work; and in the production process for Japanese sake.

Onomichi in Hiroshima was once one of the three largest production areas of Kakishibu. Kakishibu from Onomichi was called "Onomichi-shibu" and was widely traded in Japan. After World War II, demand for Kakishibu decreased sharply due to the influence of Western culture and the increase in synthetic and petroleum products. Though the factories and manufacturers were closed down and gone, the trees that produce the persimmons still remain. Many of the trees, which are over 100 years old, still grow in the mountain areas surrounding Onomichi.

Founded by an entrepreneurial descendant of a persimmon farmer, "Onomichi Kakien" has revived this traditional dye while learning from nature and these surviving persimmons. Recently, Kakishibu has been recognized as a great alternative to synthetic dyes by more people interested in nature and wellness because it has many natural, beneficial properties, such as deterring insects and having an anti-mold effect for wood and cloth. We believe Kakishibu is a wonderful dye that can be shared with the world and the new generations.

EASY TO USE

Just apply directly or dilute with water! No fixer needed. Use water without metals or chlorine for better results.

WATER BASED

No mess! You can clean your hands and brushes with water.

NURTURE

6 months for fermentation and more than 2 years for aging.

HEALTHY

Non-toxic, water-resistant, antiseptic, insect repellent, mildew-proof.

ORGANIC

No additives! Instead of using a chemical treatment to remove the fermentation scent, we use a heat treatment to remove the bacteria and reduce the odor. The balsamic vinegar or food compost-like smell will start to disappear after a week.

BOTANICAL

Over time, the dyed color becomes deeper by the oxidation of the tannin.

LONG-LASTING

You can preserve Kakishibu dye in a pack for years! Unopened Kakishibu can be saved even longer, and it will become a rich color as aging progress.

UPCYCLE

You can restore old items or make new items look vintage.

Using Kakishibu dye

NOTE:

Start dyeing with lighter tone because the color gets darker in a month. Kakishibu produces a sheer brown color.

Avoid contact with iron metals until it dries. The contact area will react and turn black.

If Kakishibu dye changes texture to become thicker or a gel, soak the package in hot water.

If white colored sediment settles at the bottom of the package, just leave until the end. Do not mix. It is impurities generated during aging which does not affect dye. By filtering with a strainer or cheesecloth to remove it, you can use Kakishibu dye until the end.

After opening, it is best to remove as much air as possible from the package and close the cap tightly. Store in a cool, dark place.

How to Apply to Cloth - Dyeing

Prewash the cloth with a mild detergent to remove starch and dirt if needed.

Soak cloth in water about 30 minutes before dyeing.

Dilute the Kakishibu with water 2 or 3 times the amount of Kakishibu.

There are two ways to apply Kakishibu to cloth. Kakishibu can be applied directly with a brush, or the cloth can be soaked in a Kakishibu dye bath.

Dry the cloth in the shade. Once it dried, hang in the sun to get darker color. Rotate the cloth to get even sun exposure.

If you prefer a wrinkled texture, you can squeeze the fabric while dyeing and wringing.

Repeat the process of dyeing and drying until you reach the desired color. Keep in mind the color will darken over time. Kakishibu produces a sheer color.

The scent of the kakishibu will be quite strong on thick fabric but disappears after it is completely dried.

The texture becomes hard after drying, but softens it by washing for a few minutes in a machine.

How to Apply to Wood - Coating

Chemical-free eco house

Smooth the surface with sandpaper before applying kakishibu.

Paint along the grain of the wood in the same direction. Use a cloth to wipe the wood if the surface has bubbles.

Paint thin coats. Wait for the first layer to dry before repeating applications. Keep in mind that after one month the color will become darker. Your desired tone will appear after months.

Tips:

You can layer Kakishibu with Bengala dyes to create unique effects. Kakishibu reacts to Bengala dyes and becomes iron gray. Paint layers of Bengala first and layer Kakishibu on top to enjoy this decorative effect.

When painting, we recommend ordering a large quantity. Painting requires a larger quantity than immersion dyeing.

Three months later

One year later

How to Apply to Paper - Painting

Kakishibu can be applied to paper to stiffen or harden paper. In Japan, washi paper is cut into small pieces and pasted onto woven baskets to make a box. Kakishibu is then applied which hardens the paper and acts as a finish. This prevents the baskets from breaking easily.

Applying Kakishibu on dry paper: Follow the same directions as wood.

Try pasting old papers, scraps, magazines, or old pictures on wood or a basket. Paste the paper with glue, then let it dry. Coat with Kakishibu using a brush. Fewer than three coats will have the best results.

You can also apply Kakishibu to a paper bag, a paper woven basket or any craft paper!